Maizhuang Daoshu Town, Danyang City , Jiangsu P, China +86-511 86675547 [email protected]

Suction dampeners aid in keeping a pump system somewhat smoother, ie less bumps or jumps. These bumps can arise for various reasons, such as the way the pump is constructed, how quickly it operates, or the thickness of the liquid it’s pumping. If left unmanaged, these bumps can damage the pump, and reduce its effectiveness.

Suction dampeners absorb pressure shifts that occur as the pump operates. They have a pliable segment that expands and contracts like a balloon to accommodate the pressure. This, in turn, keeps the liquid flowing smoothly and reduces the impact of the bumps on the pump.

There is one very good reason to use suction dampeners, and that’s that a pump is most efficient when it can operate in flow range, and suction stabilizers can help make that happen. Suction dampeners can prevent damage to the pump and its components by eliminating the bumps. This can prolong the life of the pump and reduce maintenance costs.

Suction dampeners are highly necessary for various industries utilizing pumps. In applications such as oil and gas, chemical processing, and water treatment, pumps regularly operate under intense pressure and punishing conditions. If the bumps are not regulated, these pumps can suffer issues such as cavitation and vibrations that can lead to their failure.

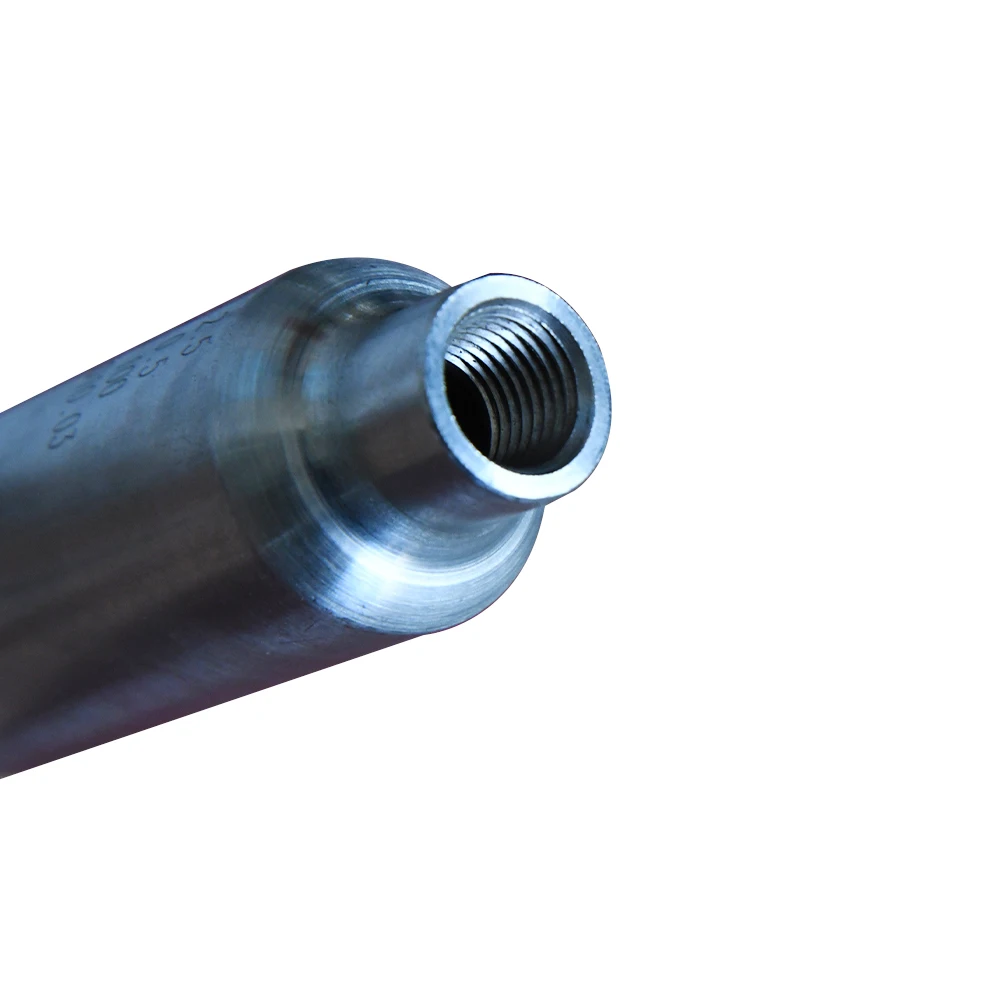

Bladder-type dampeners are the most popular and typically less expensive. The bumps are absorbed by a flexible part. Diaphragm type dampeners operates in the same way, but include a different part called a diaphragm. They’re typically stronger, able to tolerate higher pressures.

The relationship between a properly working suction dampener and the quality of the pulp being produced is clear, so it is essential to ensure your equipment is functioning as it should. Tips might include pressure checks, a visual inspection of the flex part for damage and tightness of all the connections.

It’s also a good idea to scroll search for the manufacturer’s directions on how to maintain and replace the parts. Knowing how to care for your suction dampener will help it last longer and will help to keep your pump system running more smoothly.

Our company is certified under ISO9001 and GB/T19001 quality management systems, ensuring that all products meet rigorous international standards for reliability, safety, and customer satisfaction.

Our professional team provides end-to-end technical support—from pre-sales consultation to after-sales service—including customized engineering solutions, nitrogen charging equipment, and responsive maintenance support to ensure optimal system performance.

With over 30 years of experience, we specialize in designing and producing high-quality bladder and diaphragm accumulators, leveraging strong technical capabilities and well-equipped testing facilities to ensure superior performance and durability.

We offer a wide range of shell materials (including 304/316L stainless steel and duplex stainless steel) and bladder/diaphragm materials (such as NBR, FKM, EPDM), supported by a full-time R&D team that provides tailored solutions for diverse industrial applications.