Maizhuang Daoshu Town, Danyang City , Jiangsu P, China +86-511 86675547 [email protected]

The hydraulic brake accumulator is an essential element of the car braking system. They are designed to store pressurized hydraulic fluid to assist in braking. When you step on the brake in your car, the hydraulic brake accumulator transfers the stored up pressure to the brakes so they can stop your vehicle.

A hydraulic brake accumulator serves a very important purpose in enhancing a vehicle's braking ability. By keeping hydraulic fluid pressurized, it ensures that the brakes will have a steady and dependable stream of fluid. This serves to offer a rapid and powerful reaction when you hit the brake, lending itself to not only heightened control, but also increased power to stop your vehicle.

As with all parts of a car, hydraulic brake accumulators need to be correctly serviced to make them work as intended. The oil accumulator needs to be regularly inspected and checked whether there is any leaking or crack. And make sure that there is always the right amount of hydraulic fluid and replace the hydraulic fluid if you must to prevent any problem with the braking system.

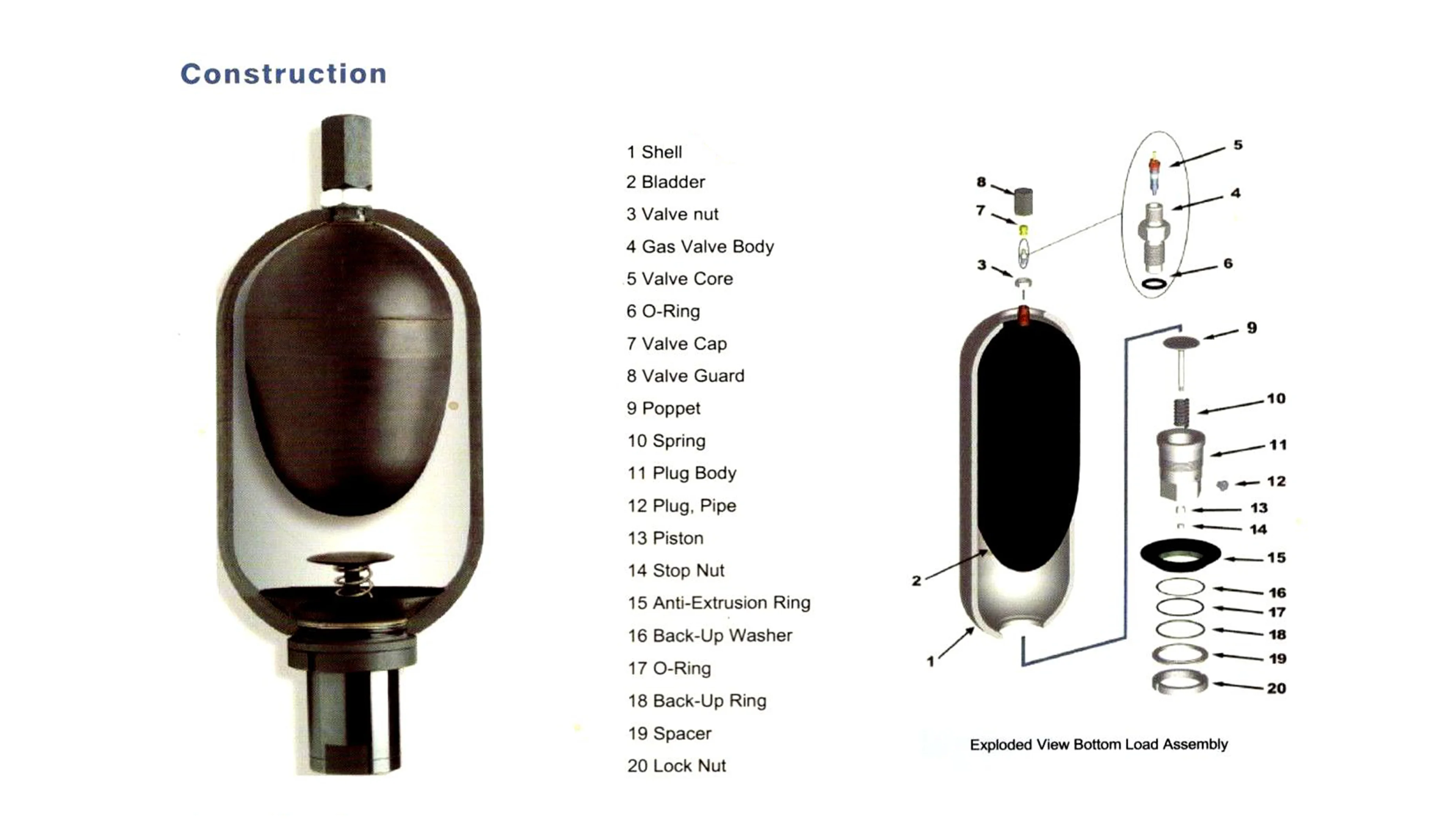

There are a variety of hydraulic brake accumulators known in the art. There are a few standard types such as the diaphragm accumulator, the piston accumulator or the bladder accumulator. All are designed and constructed slightly differently, but share the same end goal of storing and holding hydraulic fluid under pressure for your brakes.

There are numerous benefits of utilizing hydraulic brake accumulators in automotive vehicles. Among the primary advantages is improved braking response, as the accumulator provides a steady and consistent hydraulic supply to the brakes. This results in improved handling and braking performance which helps improve overall vehicle safety. Furthermore, hydraulic brake accumulators assist in extending the life of the braking system, resulting in wear and tear parts that last longer with lower maintenance costs.

Our company is certified under ISO9001 and GB/T19001 quality management systems, ensuring that all products meet rigorous international standards for reliability, safety, and customer satisfaction.

Our professional team provides end-to-end technical support—from pre-sales consultation to after-sales service—including customized engineering solutions, nitrogen charging equipment, and responsive maintenance support to ensure optimal system performance.

We offer a wide range of shell materials (including 304/316L stainless steel and duplex stainless steel) and bladder/diaphragm materials (such as NBR, FKM, EPDM), supported by a full-time R&D team that provides tailored solutions for diverse industrial applications.

With over 30 years of experience, we specialize in designing and producing high-quality bladder and diaphragm accumulators, leveraging strong technical capabilities and well-equipped testing facilities to ensure superior performance and durability.